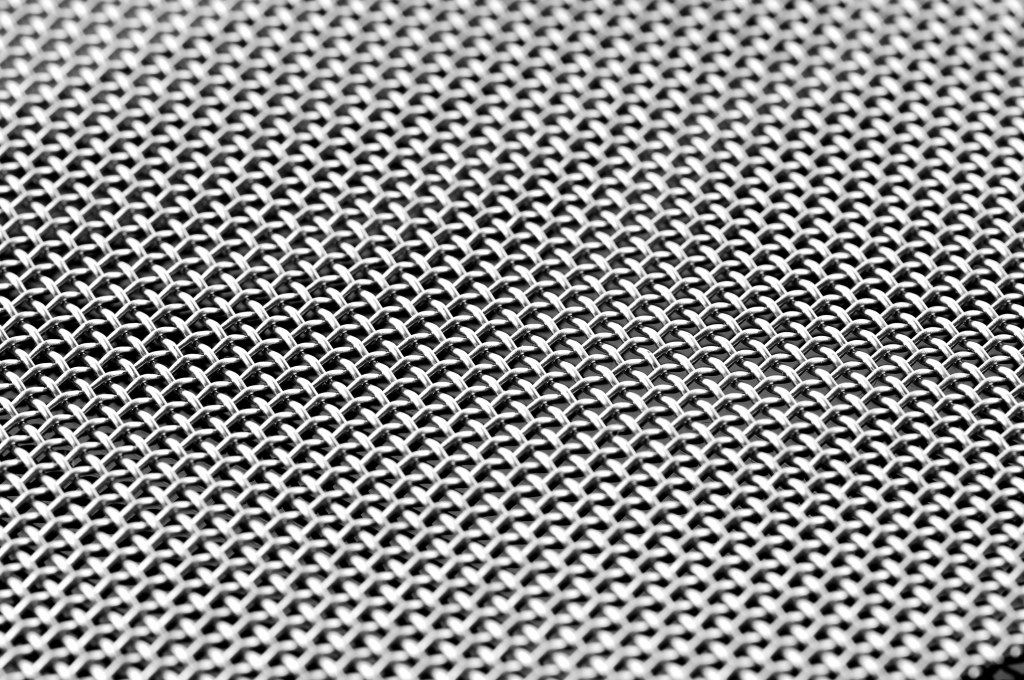

In industrial systems where hydraulic fluids and lubricants are vital to the operation of machinery, ensuring cleanliness and purity is non-negotiable. Specialized hydraulic and oil filters play a critical role in maintaining this purity, preventing contamination that could damage sensitive components, cause wear, or reduce efficiency. At the heart of many of these filters lies a high-performance filtration medium: stainless steel wire mesh.

This article explores the indispensable role of stainless steel wire mesh in hydraulic and oil filtration systems and why it is favored across a wide range of demanding applications.

Essential Roles of Stainless Steel Wire Mesh in Filtration Systems

The performance of a hydraulic or oil filter largely depends on the properties of the filtration media. Stainless steel wire mesh provides a unique combination of mechanical strength, filtration precision, and chemical resilience, making it a top choice for engineers and maintenance professionals.

1. High Filtration Efficiency

The primary function of any filter is to capture contaminants while allowing clean fluid to pass through. Stainless steel wire mesh achieves this with exceptional consistency. It can be woven with precise pore sizes to capture particles like dust, metal shavings, or sludge without obstructing flow. This ensures a continuous, smooth operation of hydraulic and lubrication systems.

2. Superior Pressure Resistance

Industrial hydraulic systems often operate under high pressure. Traditional filter materials may collapse or deform under such conditions. In contrast, stainless steel wire mesh maintains its structural integrity, offering reliable performance even under extreme pressure. This helps maintain consistent filtration efficiency over extended use.

3. Resistance to Heat and Corrosive Fluids

Hydraulic fluids and lubricants often encounter elevated temperatures and may include chemically aggressive additives. Stainless steel wire mesh withstands these conditions with ease, resisting oxidation, corrosion, and breakdown. This durability makes it suitable for both high-temperature and chemically demanding environments such as offshore rigs, mining equipment, or high-speed machinery.

4. Reusability and Cost Efficiency

One of the significant advantages of stainless steel mesh filters is their reusability. Unlike disposable filter media that need frequent replacement, stainless steel mesh can be cleaned, restored, and reused multiple times. This reduces downtime, minimizes waste, and leads to lower maintenance costs over the filter’s lifespan.

Common Stainless Steel Grades Used in Hydraulic and Oil Filters

Different applications may require different properties, and the choice of stainless steel grade directly affects performance. The most commonly used materials include:

-

304 Stainless Steel – Known for its good corrosion resistance and durability. It is suitable for most general-purpose hydraulic and oil filters.

-

316 Stainless Steel – Offers superior resistance to harsh chemicals and saltwater, making it ideal for marine, chemical, and offshore applications.

-

316L Stainless Steel – A low-carbon variant of 316, this grade improves resistance to intergranular corrosion and offers better weldability, suitable for high-temperature or welded components.

Each grade brings a specific benefit, and selection depends on factors like operating temperature, fluid type, and environmental exposure.

Why Choose Hightop Wire Mesh for Filtration Solutions?

At Hightop Wire Mesh, we understand the critical role filtration plays in industrial efficiency and equipment protection. That’s why we offer premium-quality stainless steel wire mesh designed specifically for hydraulic and oil filtration systems.

✔ High Precision Weaving

We use advanced weaving technology to achieve tight tolerances and uniform pore sizes, ensuring consistent and accurate filtration performance across all mesh panels.

✔ Long-Term Durability

Our stainless steel wire mesh products are engineered for long service life. They resist wear, corrosion, and fatigue, even under continuous exposure to challenging environments.

✔ Customizable Specifications

We offer a wide range of mesh counts, wire diameters, and alloy options to meet different application needs. Whether you need coarse mesh for pre-filtration or fine mesh for polishing stages, we can deliver customized solutions.

✔ Economical and Sustainable

Reusable mesh filters offer a cost-effective and environmentally friendly alternative to single-use filtration media. Reduced replacement frequency leads to lower operational costs and less waste.

In specialized hydraulic and oil filtration systems, the choice of filter media directly impacts equipment performance and system reliability. Stainless steel wire mesh stands out as a highly effective, long-lasting, and versatile solution. Its unique combination of mechanical strength, precision filtration, heat and chemical resistance, and reusability makes it an ideal choice for demanding industrial applications.

When you choose Hightop Wire Mesh, you’re investing in quality, performance, and longevity. Our tailored filtration mesh solutions help maximize your operational uptime while minimizing maintenance and replacement costs—making us the trusted partner for high-performance filtration.

Request a Quote

Please email us by the contact form below, we will get back to you as soon as possible.