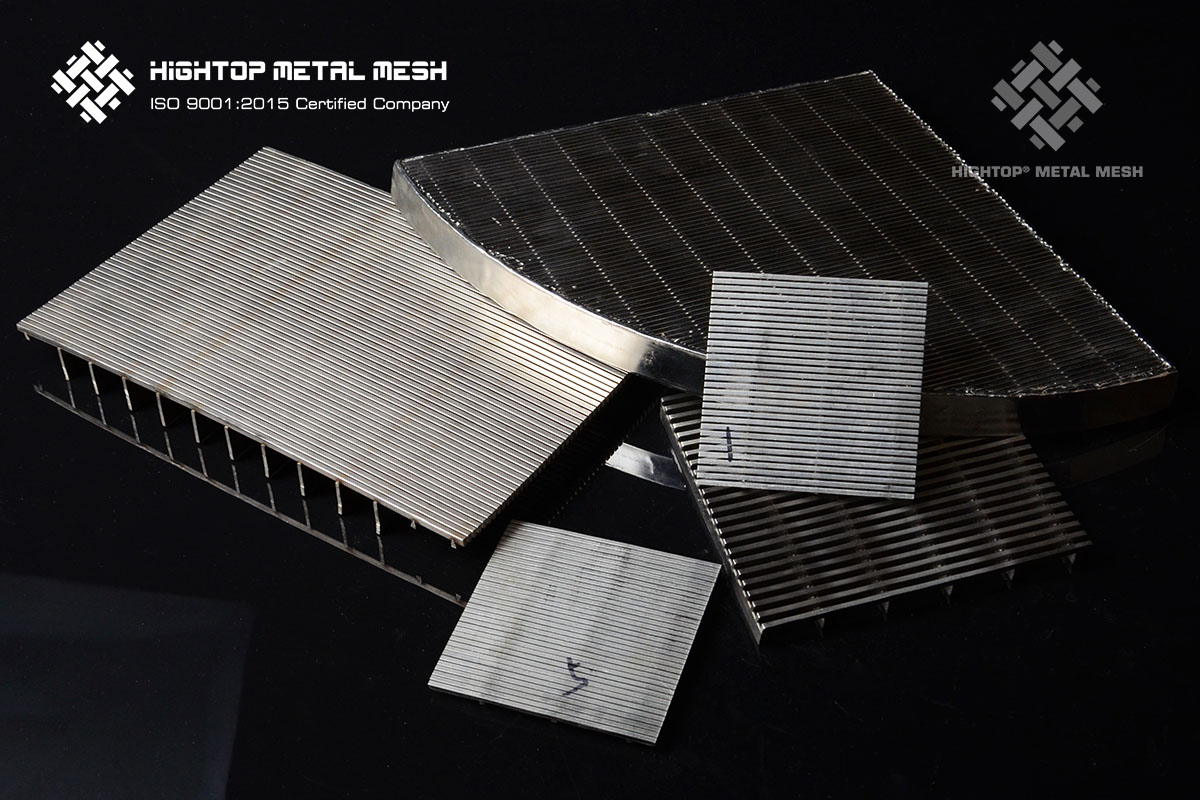

Stainless Steel Woven Mesh

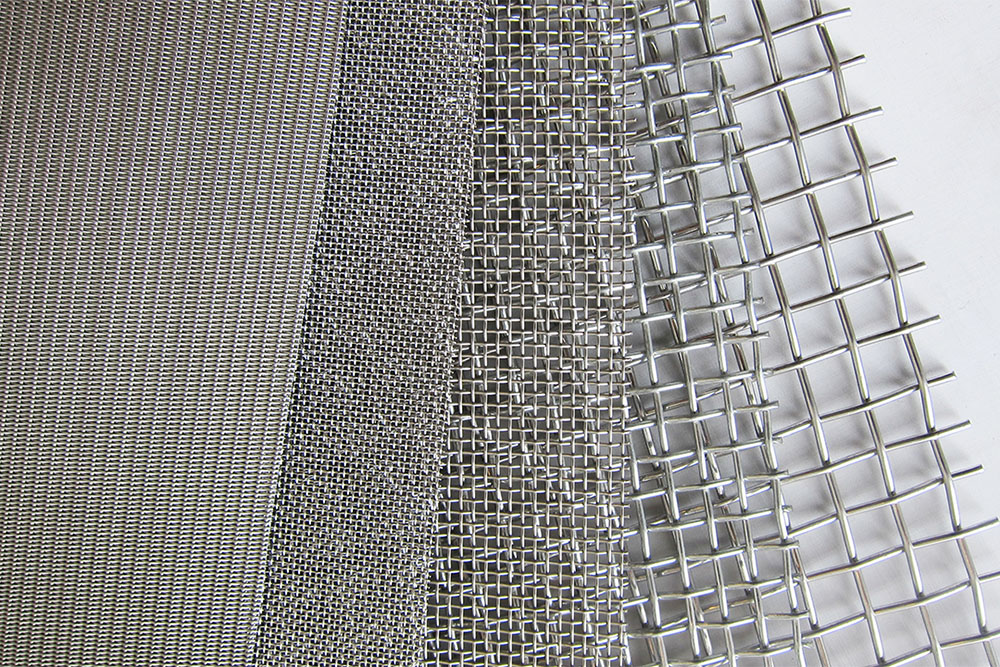

Hightop Metal offers various weave types of stainless steel woven mesh to fulfill your requirements, including plain weave, twill weave and Dutch weave, etc..

- Material: AISI 302, 304, 304L, 316, 316L, 321, 310, 904L, etc.

- Wire diameter: 0.0008″-0.08″ (0.02-2.0 mm)

- Mesh counts: 1-500 mesh

- Opening in Micron: 1-20,000 microns

- Types of Weave: Plain Weave, Twill Weave and Dutch Weave

- Types: Available in cloth, panels and sheets.

- Features: Precise opening, uniform mesh, excellent corrosion resistance, strong and durable.

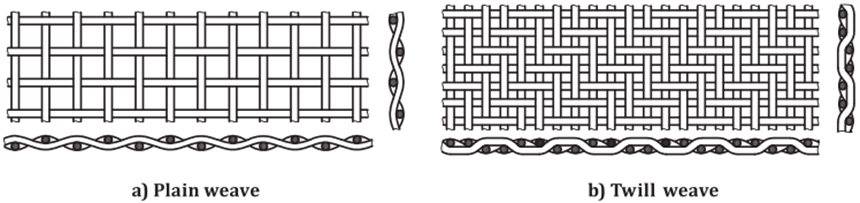

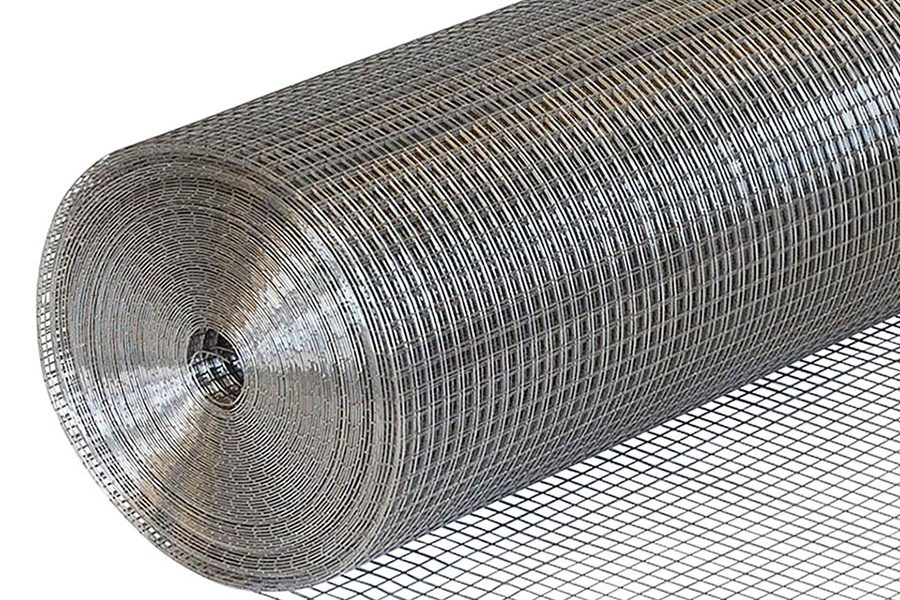

Plain & Twill Weave

Plain weave and twill weave stainless steel woven mesh is commonly used for sieving, filtration, and security applications. Plain weave is woven by passing the shute wire over and under the warp wire successively, creating a square opening mesh. Twill weave is woven by passing the shute wire over and under two strands of warp wire, creating denser and sturdier meshes.

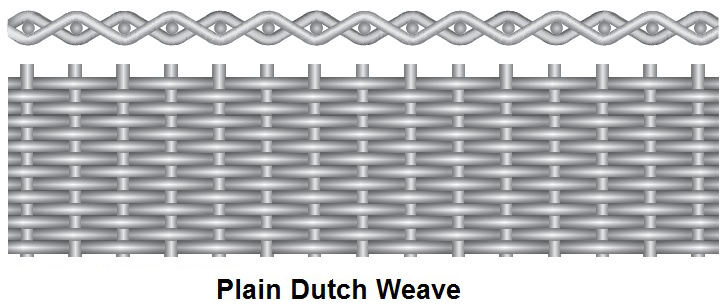

Plain Dutch Weave

Plain Dutch stainless steel woven mesh has a similar weaving pattern as in plain, except the diameter of warp wire is larger than shute wire.

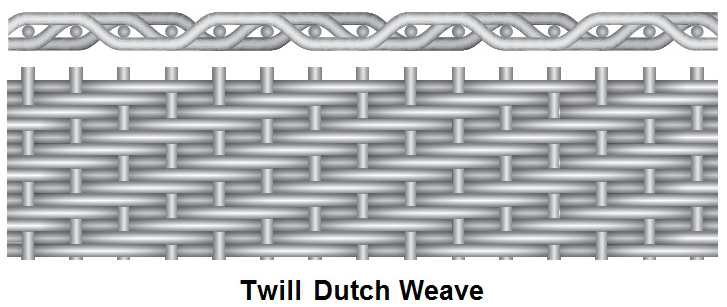

Twill Dutch Weave

Twill Dutch weave stainless steel wire screen combines the weaving pattern of twill and Dutch, the larger diameter warp successively passes over and under smaller diameter shute wire creating a tight mesh that can withstand heavy pressure. Since Dutch weave creates a stronger and more durable structure than plain weave does, this type of mesh provides superior liquid filtration capabilities and it is your ideal option for petrochemical, aerospace, pharmaceutical, mining, and wastewater treatment facilities.

Reverse Plain & Twilled Dutch Weave

Reverse Dutch weave stainless steel woven wire screen also uses two different sizes of wires in weaving but reversing the method used in Dutch weave. The smaller wires are using in the warp direction and are woven with a larger shute wire. The smaller wires are woven as closely as possible to provide a finer and tighter mesh for filtering. The larger wire is used to strengthen and support the whole mesh.

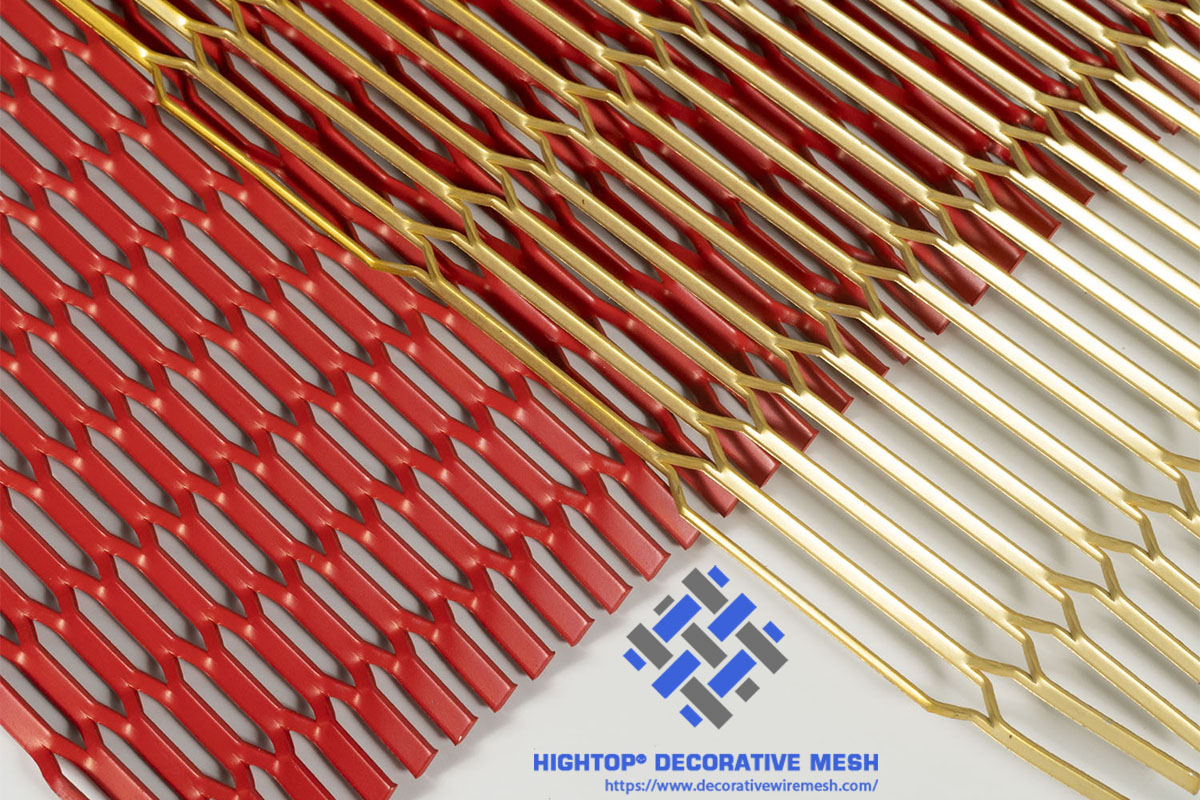

Application for Stainless Steel Woven Wire Mesh Screen:

- Filtration

- Sieving

- Metal fencing

- Room partition

- Security screen

- Window screen

- Weave Types

-

Plain & Twill Weave

Plain weave and twill weave stainless steel woven mesh is commonly used for sieving, filtration, and security applications. Plain weave is woven by passing the shute wire over and under the warp wire successively, creating a square opening mesh. Twill weave is woven by passing the shute wire over and under two strands of warp wire, creating denser and sturdier meshes.

Plain Dutch Weave

Plain Dutch stainless steel woven mesh has a similar weaving pattern as in plain, except the diameter of warp wire is larger than shute wire.

Twill Dutch Weave

Twill Dutch weave stainless steel wire screen combines the weaving pattern of twill and Dutch, the larger diameter warp successively passes over and under smaller diameter shute wire creating a tight mesh that can withstand heavy pressure. Since Dutch weave creates a stronger and more durable structure than plain weave does, this type of mesh provides superior liquid filtration capabilities and it is your ideal option for petrochemical, aerospace, pharmaceutical, mining, and wastewater treatment facilities.

Reverse Plain & Twilled Dutch Weave

Reverse Dutch weave stainless steel woven wire screen also uses two different sizes of wires in weaving but reversing the method used in Dutch weave. The smaller wires are using in the warp direction and are woven with a larger shute wire. The smaller wires are woven as closely as possible to provide a finer and tighter mesh for filtering. The larger wire is used to strengthen and support the whole mesh.

- Specifications

- Applications

-

Application for Stainless Steel Woven Wire Mesh Screen:

- Filtration

- Sieving

- Metal fencing

- Room partition

- Security screen

- Window screen

Request a Quote

Please email us by the contact form below, we will get back to you as soon as possible.