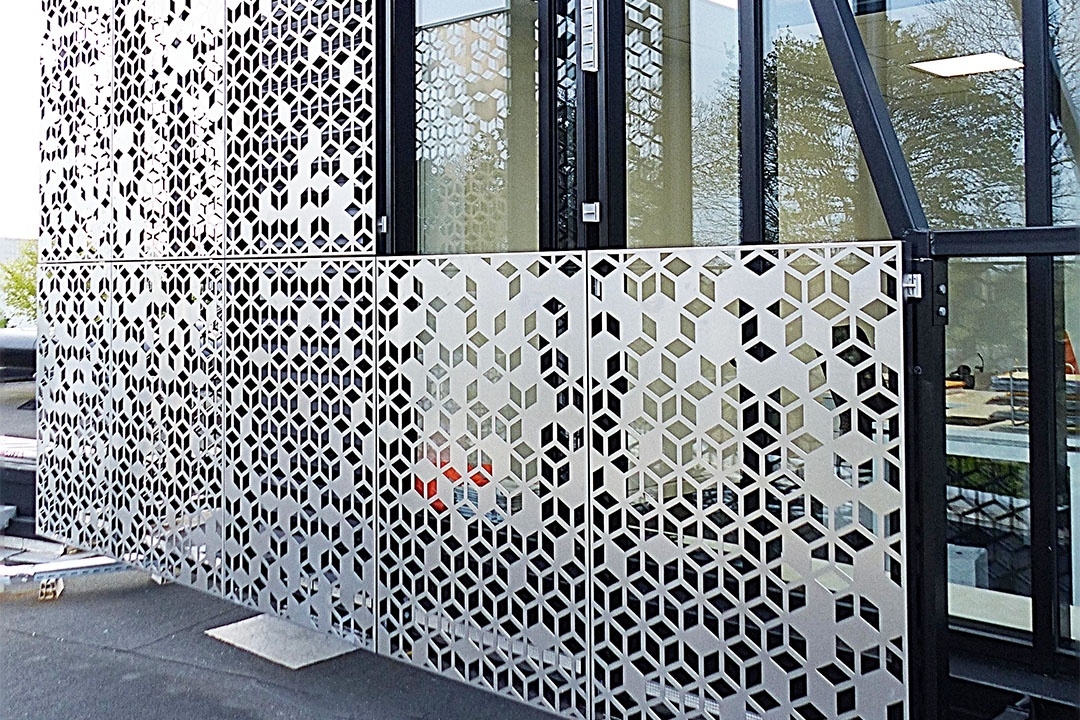

Perforated Stainless Steel Sheet Metal Overview

Perforated stainless steel sheet metal is one of the most widely used metal materials in architecture, industry, decoration, and engineering. It is produced by punching precise holes into stainless steel sheets, forming a durable and functional perforated steel mesh structure.

Also known as perforated stainless steel screen, perforated metal screen, or decorative punched metal sheets, this material combines strength, corrosion resistance, ventilation, and aesthetic design.

As professional perforated metal suppliers, manufacturers, and exporters, Hightop Metal Mesh provides high-quality perforated stainless steel sheet metal solutions for global projects.

What Is Perforated Stainless Steel Screen?

A perforated stainless steel screen is a metal sheet processed by CNC punching or stamping to create uniform or customized hole patterns. These perforations enhance airflow, light transmission, acoustic performance, and decorative value.

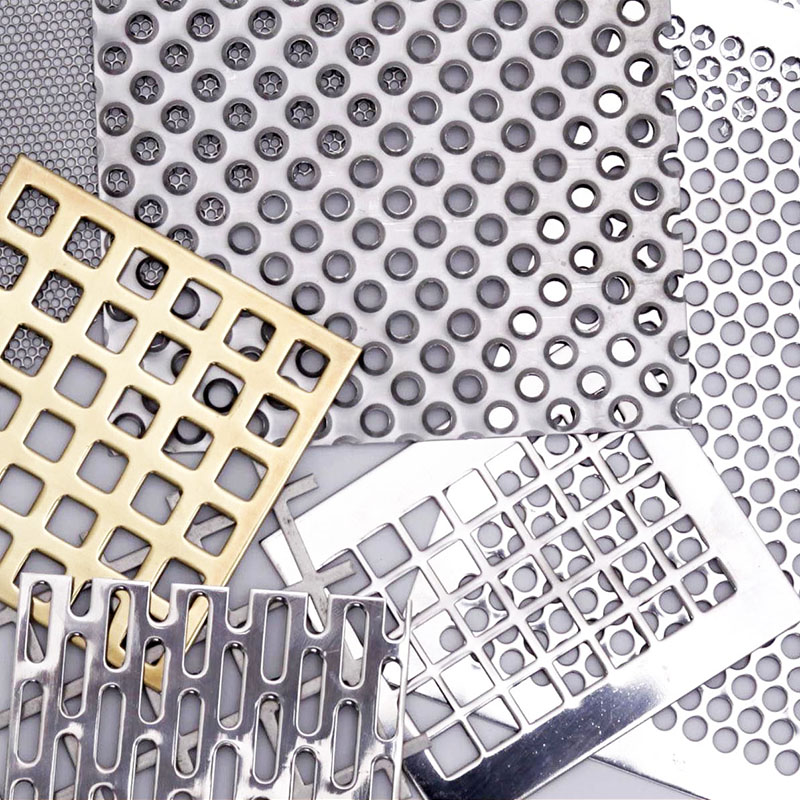

Common Hole Types in Perforated Metal Screen

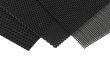

- Round hole perforated steel mesh

- Square hole perforated stainless steel sheet

- Slotted hole perforated metal screen

- Hexagonal perforated steel mesh

- Diamond hole decorative punched metal sheets

- Custom decorative patterns

Different hole patterns directly affect strength, transparency, and visual appearance, making perforated stainless steel sheet metal suitable for multiple industries.

Round Hole Perforated Metal

Specifications of Perforated Stainless Steel Sheet Metal

Professional perforated metal suppliers offer a wide range of specifications to meet diverse project requirements:

-

Material: Stainless steel 304, 316, 316L

-

Thickness: From thin gauge to heavy-duty plates

-

Width: Up to 72 inches (1830 mm)

-

Hole size: Micro holes to large apertures

-

Sheet size: Customized dimensions

-

Surface treatment: Polished, brushed, coated, anodized

With advanced production equipment, perforated steel mesh can be manufactured with high precision and stable quality.

Applications of Perforated Stainless Steel Sheet Metal

Due to its excellent performance, perforated stainless steel sheet metal is widely used in architectural, industrial, decorative, and commercial fields.

Architectural Applications

-

Building facade panels

-

Wall cladding systems

-

Ceiling panels

-

Balcony panels and railings

-

Stair panels

-

Sunshade and curtain wall systems

Decorative Applications

-

Interior partitions

-

Metal screens

-

Decorative punched metal sheets

-

Furniture and design elements

Industrial Applications

-

Machine protective covers

-

Equipment enclosures

-

Filtration and screening systems

-

Ventilation panels

Acoustic and Environmental Applications

-

Sound-absorbing wall panels

-

Noise control barriers

-

Air ventilation systems

Commercial and Daily Applications

-

Speaker grilles

-

Kitchenware products

-

Stainless steel trays and baskets

The broad application range makes perforated stainless steel screen a core product of many perforated metal suppliers worldwide.

Advantages of Perforated Steel Mesh

Compared with other metal materials, perforated steel mesh offers significant advantages:

High Strength and Durability

Perforated stainless steel sheet metal maintains structural integrity even after punching, ensuring long-term performance.

Excellent Corrosion Resistance

Stainless steel perforated metal screen is ideal for outdoor, marine, and humid environments.

Superior Aesthetic Design

Decorative punched metal sheets enhance architectural and interior design aesthetics.

Ventilation and Light Transmission

Perforated metal screens provide excellent airflow and light diffusion.

Customization and Flexibility

Hole patterns, thickness, and dimensions can be tailored by professional perforated metal suppliers.

Why Choose Professional Perforated Metal Suppliers?

Choosing reliable perforated metal suppliers and manufacturers ensures:

-

High production precision

-

Stable quality control

-

Competitive factory prices

-

Custom perforated steel mesh solutions

-

Bulk order capability

-

International export experience

As a specialized manufacturer, Hightop Metal Mesh integrates design, production, and global supply, making it a trusted partner among perforated metal suppliers.

Perforated Stainless Steel Sheet Metal vs Other Metal Sheets

| Feature | Perforated Stainless Steel Sheet Metal | Solid Metal Sheet |

|---|---|---|

| Ventilation | Excellent | Poor |

| Weight | Lighter | Heavier |

| Aesthetic | High | Limited |

| Application | Wide | Limited |

| Customization | High | Low |

This comparison explains why perforated stainless steel sheet metal is increasingly preferred by architects and engineers.

Stainless Steel Sheet with Holes

FAQ About Perforated Stainless Steel Sheet Metal

What are the uses of perforated stainless steel sheet metal?

Perforated stainless steel sheet metal is used in building facades, wall cladding, ceilings, partitions, industrial equipment, filtration systems, speaker grilles, and decorative applications. It is suitable for both functional and decorative purposes.

What are the advantages and disadvantages of perforated stainless steel mesh?

Advantages:

-

High strength and corrosion resistance

-

Decorative appearance

-

Good ventilation and light transmission

-

Wide customization options

-

Long service life

Disadvantages:

-

Higher cost than carbon steel

-

Complex hole patterns increase manufacturing costs

-

Thick sheets may increase weight and installation cost

How to choose the right perforated metal product?

To select the right perforated stainless steel screen, consider:

-

Application requirements

-

Material grade (304 or 316)

-

Hole size and pattern

-

Sheet thickness

-

Environmental conditions

-

Budget and design needs

Consulting professional perforated metal suppliers helps ensure the optimal solution for your project.

Request a Quote

Please email us by the contact form below, we will get back to you as soon as possible.